Servo Motor Repair Services in Atlanta, GA

Servo Motor Repair Services in Atlanta, GA provide manufacturers, industrial facilities, and automation driven operations with professional support when servo motors begin to fail, lose accuracy, or stop functioning altogether. This service is intended for businesses that rely on servo controlled motion for precision, repeatability, and efficiency across production environments throughout the Atlanta metropolitan area.

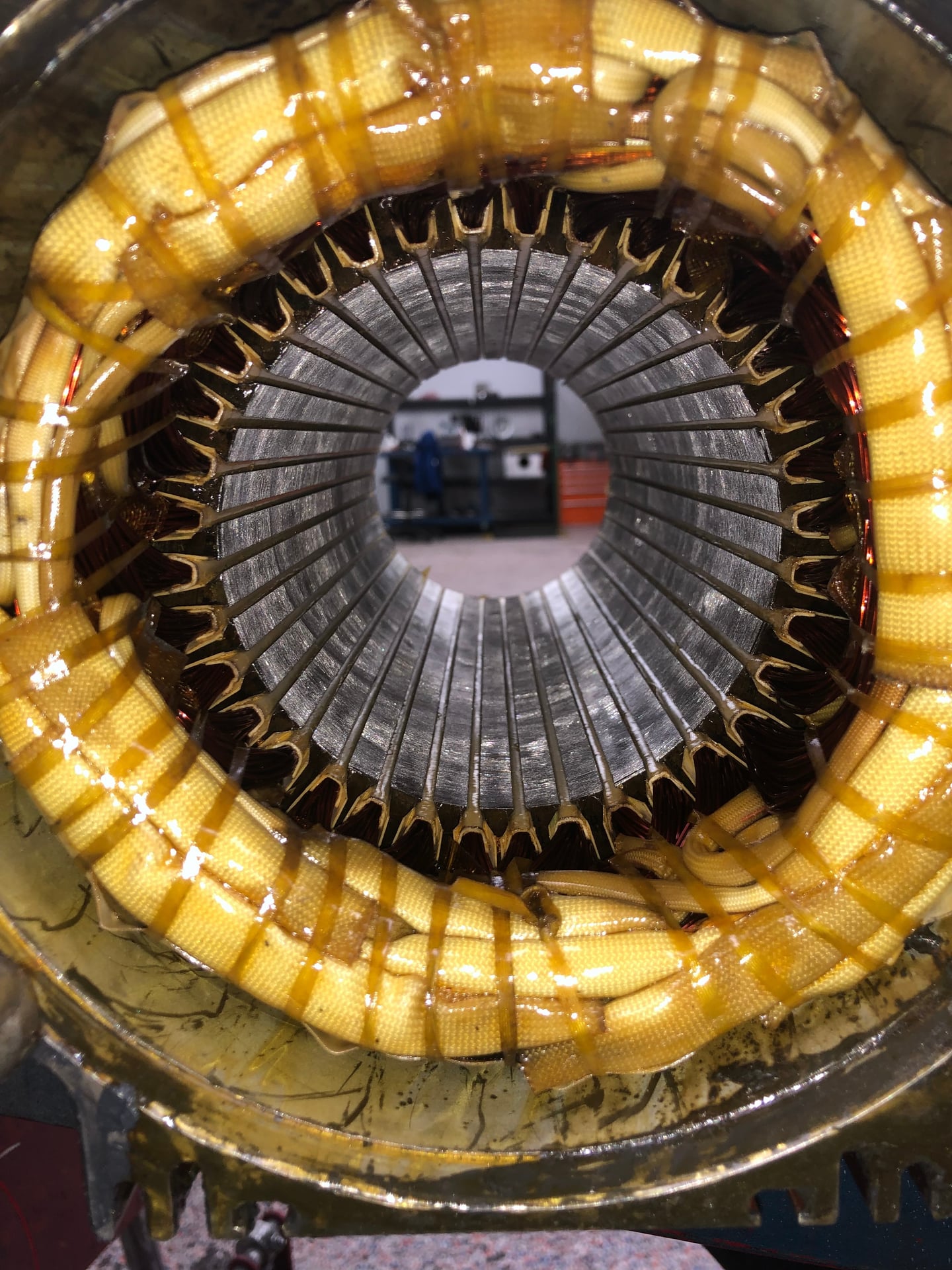

Servo motor repair focuses on restoring performance, accuracy, and reliability to existing motors rather than forcing premature replacement. For many Atlanta facilities, this approach supports operational continuity while controlling maintenance costs and minimizing downtime.

Servo Motor Repair Services in Atlanta, GA for Precision Motion Systems

Servo motors play a critical role in industrial automation by controlling speed, position, and torque with a high degree of accuracy. These motors are commonly used in applications where precise motion and synchronization are essential.

Servo motor repair services in Atlanta, GA support systems used in manufacturing, packaging, material handling, robotics, and CNC environments. When servo motors degrade or fail, overall system performance can be affected, leading to production errors, mechanical stress, or unplanned downtime.