PLC & HMI Repair Services in Atlanta, GA

PLC & HMI Repair Services in Atlanta, GA support manufacturers, industrial facilities, and automation driven operations when programmable logic controllers and human machine interfaces begin to fail, behave unpredictably, or stop communicating with equipment. This service is designed for businesses that rely on PLC controlled processes and operator interface systems to manage production, safety, and system visibility across the Atlanta metropolitan area.

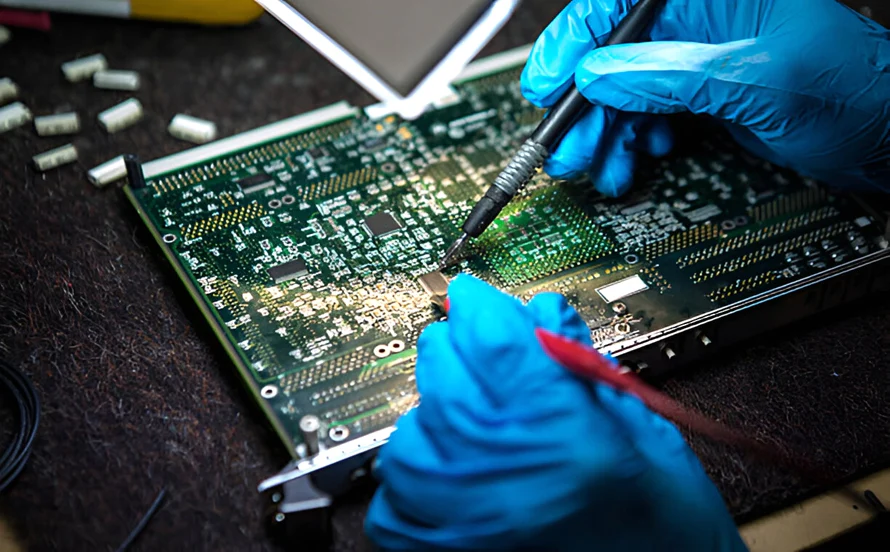

PLC and HMI repair focuses on restoring reliable control logic, system communication, and operator interaction without unnecessary replacement. For many Atlanta facilities, repairing existing PLC and HMI components helps maintain system consistency while minimizing downtime and disruption.

PLC & HMI Repair Services in Atlanta, GA for Industrial Control Systems

PLCs and HMIs serve as the central control and interaction points within industrial automation systems. PLCs execute control logic that governs machinery and processes, while HMIs provide operators with real time system status, alerts, and control access.

PLC & HMI Repair Services in Atlanta, GA are commonly used in manufacturing plants, processing facilities, warehouses, and industrial environments where control reliability and system visibility are critical. When these components fail, operations can quickly become unsafe, inefficient, or completely inoperable.